-

STERIONIZER™

- The STERIONIZER™ ionization concept is an excellent solution for all food processing, food packaging and food storing areas with critical requirements of air purity and sterility.

The system ensures reliable and consistent conditions, helps to reduce the spread of pathogens.

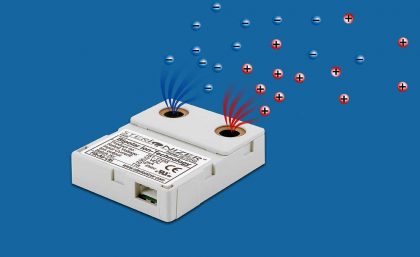

The basic principal is the permanent flushing of the area with clean air reinforced with positive and negative ions.

These charged oxygen molecules O₂+ and O₂- have high chemical activity and when reacting with water molecules in the air, H₂O₂ (Hydrogen Peroxide) is formed. A chemical reaction occurs and oxidants break down the protein structure of pollutants, rendering them harmless.

STERIONIZER™ system keeps air ducts, air heat exchangers and air handling units clean and supplies ionized air in enclosed areas.

Each ionizing device is completely maintenance free and can be connected to a data-bus for supervision and monitoring. - FILT AIR Ltd. has developed the STERIONIZER™ technology, a bipolar ionization module that brings natural air in to living environments. The STERIONIZER™ restores the necessary ion levels in closed spaces.

- The STERIONIZER™ module can be easily integrated with various types of air treatment applications, including air conditioners, air purifiers, dehumidifiers, and air fans / blowers.

- The STERIONIZER™ module takes air treatment system to a higher level – compared to existing market solutions.

- The STERIONIZER™ modules are protected by several patents worldwide.

- The STERIONIZER™ ionization concept is an excellent solution for all food processing, food packaging and food storing areas with critical requirements of air purity and sterility.

-

STERIONIZER™

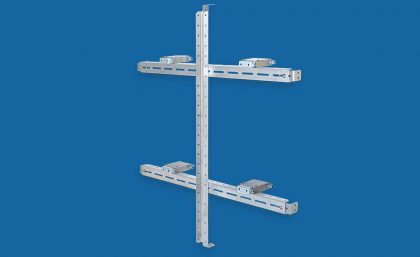

The STERIONIZER™ product family is designed to cover different customer requirements (airflow type, balancing, and installation) in a simple way. In order to comply with these client needs, the STERIONIZER™ array of products have been developed under identical mechanical and electronic interface schemes, differing only in specifications. The STERIONIZER™ window unit is based on the same technology, but differs only in dimensions in order to solve problem of installation in small places — such as the louver of an A/C system.

-

STERIONIZER™

AIRFLOW

- LAMINAR airflow has to be parallel to the ion opening plane and have equal speed at the positive and negative ion output

- TURBULENT airflow may be turbulent and the only limitation is that the airflow vector should not drive air into ion openings

- THE STERIONIZER™ effective only if the ions are dissipated in airflow

- THE STERIONIZER™ not to be powered unless the integrated system is operating and generating the required airflow

ION BALANCE

- SELF BALANCING — ion level is always balanced due to the physical design concept of the unit

- ION BALANCE — unit is balanced in the range defined, which fits the standard required ion level

ION OUTPUT defines the Ion level output for the unit

OZONE LEVEL defines the ozone level output and has to be compliant with American standard: 0.050 ppm